The Stick Maker

Alfred E. Jacques is an Onondaga Nation craftsman who continues a long-standing tradition: handcrafting traditional wooden lacrosse sticks.

By Ken Sturtz

To watch Alfred E. Jacques make a lacrosse stick is to witness an artist at work.

It may seem strange to call someone who makes a piece of sports equipment an artist. It’s hard to imagine the factory workers who churn out football helmets or basketballs as artists. But Jacques is a factory of one and you can’t buy his lacrosse sticks at the local sporting goods store.

In a tiny workshop located in a nondescript cinder-block barn on the Onondaga Nation, south of Syracuse, Jacques sits at a bench, meticulously carving a piece of hickory with a drawknife. The air carries a hint of sawdust and the room is filled with sticks in various stages of completion.

He makes approximately 200 highly sought after handmade wooden lacrosse sticks each year.

With each pass, wood shavings land at his feet. When he finishes, the stick is so smooth it almost looks like it’s been machine cut.

“I’ve been at it for 60 years; I can make it look really easy, but it’s a lot harder than people realize,” he said. “Everybody would make their own stick if it was easy.”

Jacques is among a handful of people who continue to make traditional wooden lacrosse sticks. Making a stick entails a tedious 10-month process that involves hours of cutting, carving, steaming, straightening, sanding and shellacking. The final product is a polished hickory lacrosse stick that shines like bone.

Over the years Jacques has gained a reputation as one of the craft’s finest stick makers. He’s known internationally and enjoys something akin to celebrity status in the lacrosse world. Jacques travels and lectures extensively on wooden lacrosse sticks. His sticks are prized by collectors, some of whom travel from other states to purchase sticks and see him work.

Jacques doesn’t have a website or social media page for his business and doesn’t advertise. There isn’t even a sign to alert visitors to his shop, tucked away out of sight at the bottom of a small hill, that they’re in the right place. He relies on word of mouth, but says in recent years the internet has made his sticks more popular than ever. In addition to the media coverage he’s received, he says collectors flock to online forums dedicated to wooden lacrosse sticks.

Out of necessity

Each year Jacques produces approximately 200 sticks.

He has a waiting list of orders that will take him at least two years to fill. He regularly gets calls from people looking to purchase a stick, but usually turns them away. This year he’s refused at least 75 new orders. After 60 years of making sticks, Jacques says he’s content to take his time and get each one right.

“I don’t even know if I can finish the list,” he said. “If I end up making 10 sticks a year, it’ll be 10 sticks a year.”

Jacques made his first lacrosse stick out of necessity when he was 12 years old. Growing up on the Onondaga Nation, he and his brother enjoyed playing lacrosse with friends. With no stick of his own, he was forced to borrow his father’s or one from a friend.

Lacrosse sticks then only cost about $5, but he says his family didn’t have the money.

“Then one day my father just kind of popped up and said what the heck let’s make our own,” Jacques said.

His father, Louis Jacques, understood the design concept, but had never actually made a lacrosse stick before. Undeterred, father and son marched into the woods. They found a tree, cut it down and split it into pieces. Then they began trying to bend them into the proper shape. Their first handful of attempts produced “some pretty darn ugly pieces,” but they learned together through trial and error.

In 1968, they went into business full-time making lacrosse sticks for $10 a piece. They eventually reached a production high of 12,000 sticks a year, all handmade by Jacques, his father and a handful of laborers. He says it’s mind-boggling to realize they averaged 250 sticks a week, more than Jacques makes in a year now.

“We worked every day, 24/7,” he said. “But you know when you love what you do it’s not so bad. We totally enjoyed what we were doing.”

If Jacques, who for most of his life either played or coached lacrosse, wasn’t busy playing or practicing, and his father wasn’t coaching lacrosse, they made sticks. Business was so busy that customers showed up at all hours. Many times, the family would be sitting down for a Sunday dinner together and customers would appear. Someone would have to go talk with the people and sell them some sticks before getting back to dinner.

Jacques and his father were charging about $25 a stick in the mid-1970s when lacrosse sticks with plastic heads and metal shafts became widely available. The shift from wooden to plastic sticks devastated their business, which fell off 90%. They were soon producing a mere 1,200 sticks a year.

Jacques eventually gave up making sticks full time and spent a 24-year career as a machinist, helping make rocket engine parts. He had other jobs over the years, but one constant remained.

“No matter what I did, no matter where I was working, no matter what happened, I always made sticks,” he said.

The reason was simple. Lacrosse is such an important aspect of life that it’s considered sacred by the Onondaga people. It’s a common tradition for baby boys to receive a miniature stick at birth and for men to be buried with their stick so they can play in the spirit world, explained Jacques, who is a member of the Onondaga Turtle Clan.

Tradition holds that the game was a gift from the Creator and that the spirit of the tree in the stick connects the players to Mother Earth as they play for the Creator. The game is so important that it’s said to have healing power, which is why it’s also known as the Medicine Game.

“And to actually play the game you have to have a wooden stick,” Jacques said. “There is no plastic in this, so somebody always has to keep the sticks rolling.”

Exercise in patience

To actually make a lacrosse stick to Jacques’s exacting standards is an exercise in patience.

The process begins by selecting and cutting down a tree, preferably shagbark hickory. It generally needs to be at least a century old and must be straight without any bends, twists or knots. On a recent visit to a woodlot with about 200 hickory trees Jacques chose just five.

The logs are split into eight pieces using a wooden mallet and an axe. They’re cut into smaller pieces and carved. The wood is still green and won’t bend well, so it’s left to dry for a month.

Then the stick is steamed in a giant drum until it’s pliable enough to bend around a shaping frame. It’s wrapped with wire to hold the shape and left to dry for at least six months. Later it’s steamed again and a smaller reverse bend is completed before the stick is allowed to dry for a week.

Jacques cuts the stick down with a band saw, taking care to cut with the grain instead of cutting straight. That makes it stronger. Then he carves and shapes the head by hand. One last steaming and the handle of the stick is straightened between two pieces of pipe and left to stabilize.

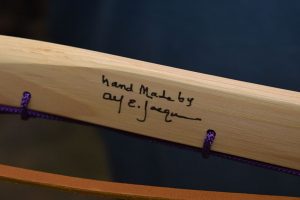

Finally, the stick is cut to the proper length and the handle cut into an octagon shape with a band saw. Jacques drills the holes in the head freehand and belt sands the stick before giving it a finer hand sanding. He burns his logo into the stick, signs it and shellacs it. The last part is fitting the pocket of rawhide and nylon. The rawhide string is made by hand. A signature purple shooting string is included.

“Everything you do is purposed to the end product,” Jacques said. “You don’t just cut, you don’t just drill.”

One of the benefits of not making thousands of sticks each year is that Jacques has the time to focus on the most minuscule details of his process. He says he thought the sticks he made 25 years ago were very high quality. He discovered that as good as they were, there was still room for improvements.

“I slowed down and I tweaked this and tweaked that and made this better and made that better,” he said. “So, I improved myself by making less.”

His high standards are evident from a pile of dozens of sticks leaning against the wall in a corner of his shop. These sticks, in various stages of completion, represent the discards. Some broke during bending. Others have knots in them. Nearly all appear fine to the untrained eye. Some might be salvageable. Most will end up as kindling.

What exactly constitutes a great stick? It turns out, is somewhat subjective. An experienced lacrosse player will often pick up a stick and feel it in their hands first and foremost, Jacques said.

They’ll be interested in the weight, the balance, the precise shape of the handle and head. They might look at 15 or 20 sticks, carefully scrutinizing the tiniest details in each.

“And that one that’s talking to him, that’s the one he’s going to get,” he said. “And they could all be of the same quality, but by being handmade they all have these little differences in them.”

‘Honor your stick’

When Jacques first began making lacrosse sticks, almost all of them were used for their intended purpose. But today the opposite is true. Lacrosse has exploded in popularity over the last half century. It has largely left the wooden stick behind in favor of its plastic counterpart.

After raising his price over the years, Jacques now gets at least $350 depending on the stick. While some people who purchase sticks use them, most are destined for a wall somewhere as a decoration. Jacques says he could make an imitation stick similar to the real thing, but not meant to be used. It would be far less work, but he wouldn’t think of doing such a thing.

While he has no illusions about where many of his sticks end up, he does make a request to his customers when they purchase one. He urges them not to leave it stuck on a wall forever and to take it down once in a while and play catch with it.

“Honor the stick for what it was made for,” Jacques said. “Use it a little and then put it back on the wall.”

Whether they’re used in a game or hung on a wall, making lacrosse sticks is physically demanding work. Jacques plans to make sticks as long as he’s able. He enjoys the work and admits he can’t sit still and always needs something to do. But at 72, he’s slowing down a bit.

“I’m getting old,” he said, laughing. “My hands hurt, everything hurts. So, I’m not making as many as I used to make.”

In addition to arthritis in his hands, wrists and shoulder, Jacques lost his mother in 2016 at age 87. A month later he noticed blood in his urine and learned he had an aggressive form of kidney cancer. He had a kidney removed and recovered. Not long after that he had a mild heart attack and had several stents inserted.

“It took a lot out of me, so I’ve slowed down,” he said.

Of course, there’s slowing down and then there’s slowing down. He used to rise every day at 5:30 a.m. Now he sleeps in until 7 a.m. and sometime after that arrives at his workshop to feed his black and white American Shorthair cats, Michelle and Obama, and start the day.

Jacques has an adult son who helped him make sticks since he was a boy; but, he has his own career as an engineer and he’s too smart to do this work his whole life, Jacques said. Over the years many people have expressed interest in learning how to make lacrosse sticks, but most quickly gave up when they realized how difficult it was.

It took a long time, but Jacques finally found an apprentice who stuck with it. He’s been learning for six years and Jacques expects him to carry on. There’s also another man on the Onondaga Nation who makes sticks.

“It’s not going to die with me,” he said. “Someone else will take the helm.”

Featured Image: Jacques uses a bandsaw to cut a handle down to size, taking care to cut with the grain of the wood to give it added strength